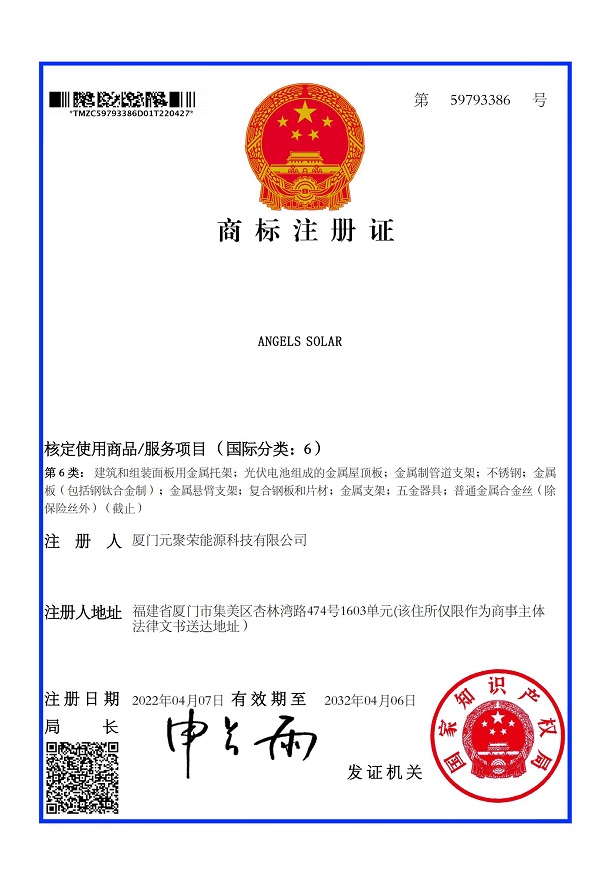

Product quality is critical to the success in the solar industry, which is an important energy industry nowadays. ANGELS SOLAR is committed to providing high-quality solar mounting systems and their ancillary products. All ANGELS SOLAR solar mounting system products and accessories are designed and manufactured to meet the requirements of JIS C 8955 and AS/NZ 1170. Our confidence comes from the strength of our factory, reliable partners.

ANGELS SOLAR's own production workshop covers an area of 6,000 square meters and has a complete solar mounting system production chain.

Our factory is equipped with advanced production equipment and instruments with integrated processing capabilities for mold manufacturing, metal stamping, and mounting system production and assembly. Our strength enables us to offer you high-precision, high-quality products.

We now have a team of experienced technical personnel and quality inspectors, who have more than 8 years of industry experience, which enables them to understand the production requirements of the solar mounting system.

With advanced quality inspection equipment, our QC team can improve its comprehensive ability to ensure that the finished products meet the requirements of clients. Pursuing the perfection of quality is not only our top priority, it is also the aim which allows every ANGELS SOLAR quality inspector to achieve occupational value.

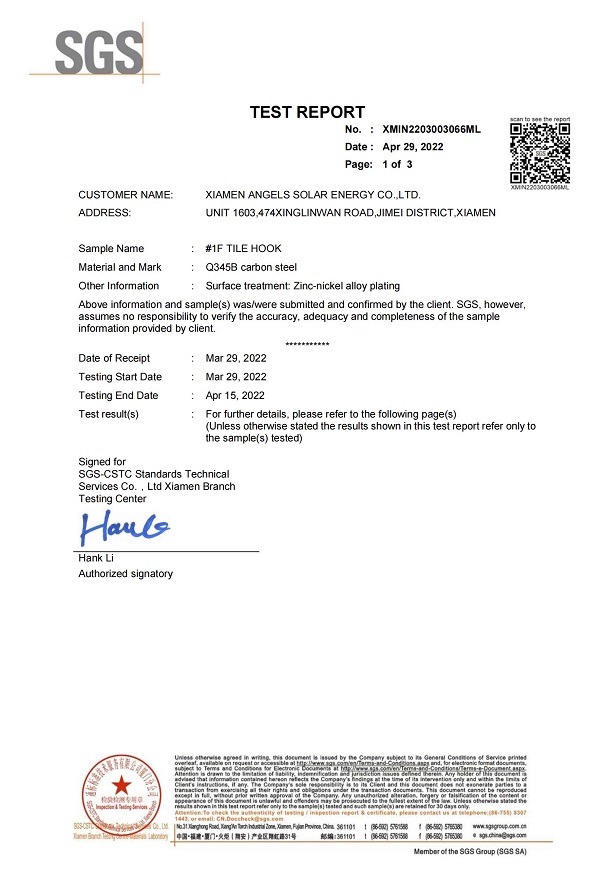

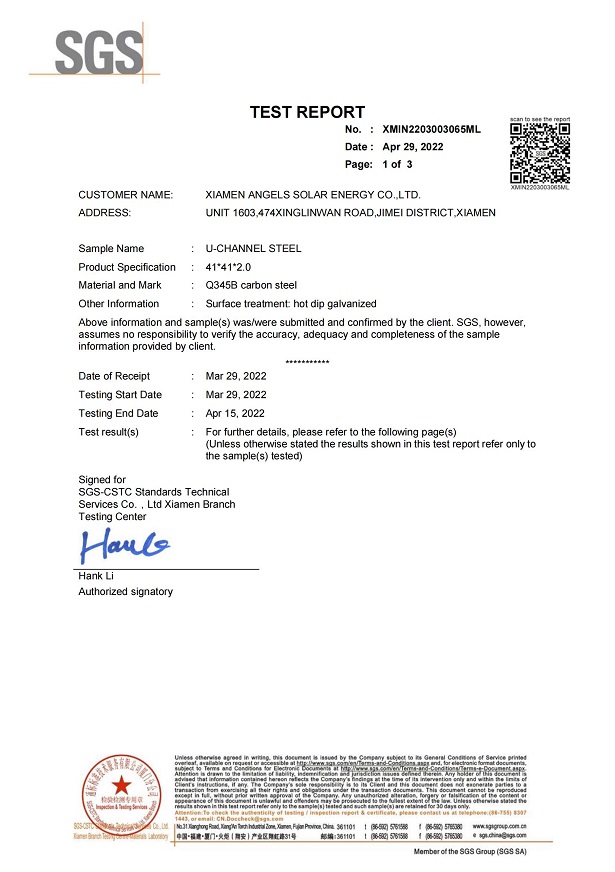

ANGELS SOLAR only uses high-quality metal materials supplied by listed companies that have, on average, ten years of cooperation with us.

For example, our aluminum profiles are produced in accordance with the GB/T 6892-2006 implementation standards and have undergone tests, at the raw material stage, for checking mechanical properties and chemical compositions. These tests include the tensile strength test, hardness testing, etc.Qualified raw materials ensure the quality of the finished products.

All solar mounting system products and matching accessories in the ANGELS SOLAR factory, from the most primitive metal materials to molded products, require multiple inspections.

We check the hardness and surface condition of the raw materials, determine whether the dimensions of the slitting and drilling are accurate, and test the oxidized coating on the surface of the product precisely. Ensuring that every detail allows us to provide our end-users with reliable, long-lasting products.